What's the difference between a relay and a contactor?

2024-11-07

Relays and contactors are both electrically operated switches, but they differ in their applications, construction, and the loads they handle. Here’s a breakdown of the main differences:

1. Purpose and Applications

- Relay: Relays are generally used for low-power applications. They control small currents in circuits, often for signaling, switching between devices, or logic operations in control systems. They’re commonly found in automotive electronics, home appliances, and small control circuits.

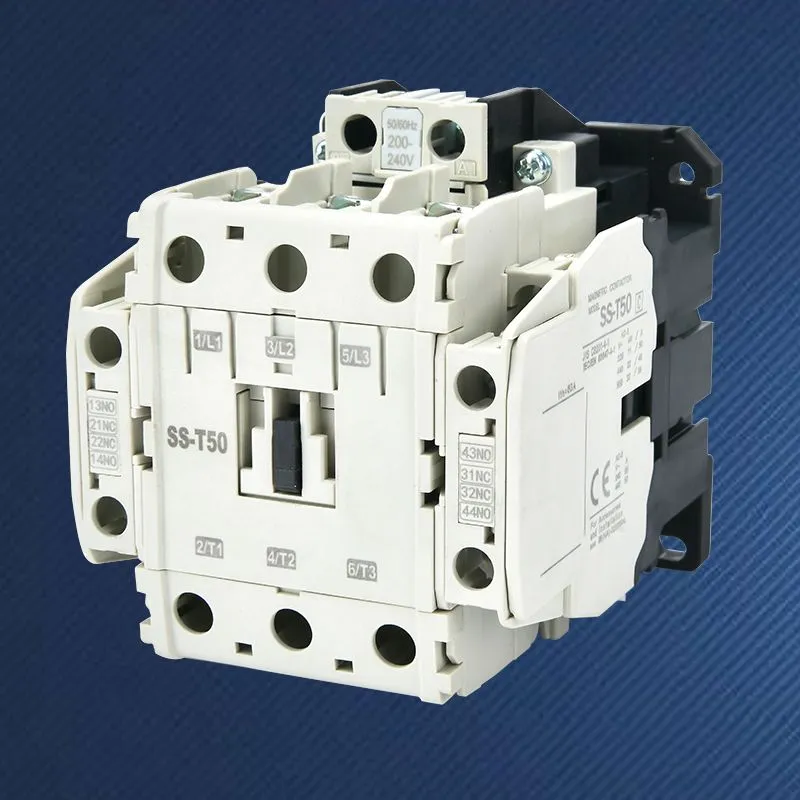

- Contactor: Contactors are designed for high-power applications. They’re typically used to control large electrical loads such as motors, heating equipment, and lighting systems. In industrial settings, contactors manage high-current circuits that require durable and high-capacity switching.

2. Current and Voltage Ratings

- Relay: Typically rated for lower current and voltage levels, often under 10A. They are not intended to handle the high inrush currents associated with motors or large equipment.

- Contactor: Rated for much higher currents, sometimes up to hundreds of amps, and designed to handle high-power circuits. They can withstand the inrush current of large motors and other high-demand loads.

3. Construction and Durability

- Relay: Relays are usually smaller and built with lighter-duty contacts since they handle lower power. They may lack arc-suppression features, as the currents they switch aren’t high enough to cause significant arcing.

- Contactor: Contactors are more robust, with larger and more durable contacts that can withstand high current and voltage. They often have arc-suppression systems to safely manage the arcs generated when switching high currents, extending their operational life.

4. Auxiliary Contacts

- Relay: Relays typically have multiple sets of contacts for control purposes and can switch several circuits at once. They may come in configurations like SPDT (Single Pole Double Throw) or DPDT (Double Pole Double Throw).

- Contactor: Usually has fewer auxiliary contacts but may include options for adding them if required. The primary contacts are designed for high-current loads, and auxiliary contacts (if available) are for low-current control signals.

5. Control Voltage

- Relay: The control voltage for a relay is typically low, often 5V, 12V, or 24V in small applications, allowing for easy integration with control circuits like microcontrollers or low-voltage logic systems.

- Contactor: While contactors can also operate on low control voltages, industrial models often use control voltages around 24V, 120V, or 220V, depending on the system requirements. High-power contactors may even be designed to handle direct AC mains control.

6. Applications with Safety Standards

- Relay: Relays are less likely to be used in applications where the safety of high-power switching is critical, as they are not rated for frequent high-load switching.

- Contactor: Contactors are often used in applications requiring adherence to industrial safety standards, especially in motor control and heavy machinery, where fail-safe operation and emergency shut-offs are essential.

Summary

- Relays are ideal for small-scale, low-power switching tasks.

- Contactors are robust, designed for high-current, high-voltage applications in industrial or commercial settings.

In general, if the application involves controlling heavy machinery or large electrical loads, a contactor is the preferred choice. For low-power control circuits, relays are usually more suitable.