What Maintenance Steps Ensure Longer Life For CNC Blades?

2025-11-04

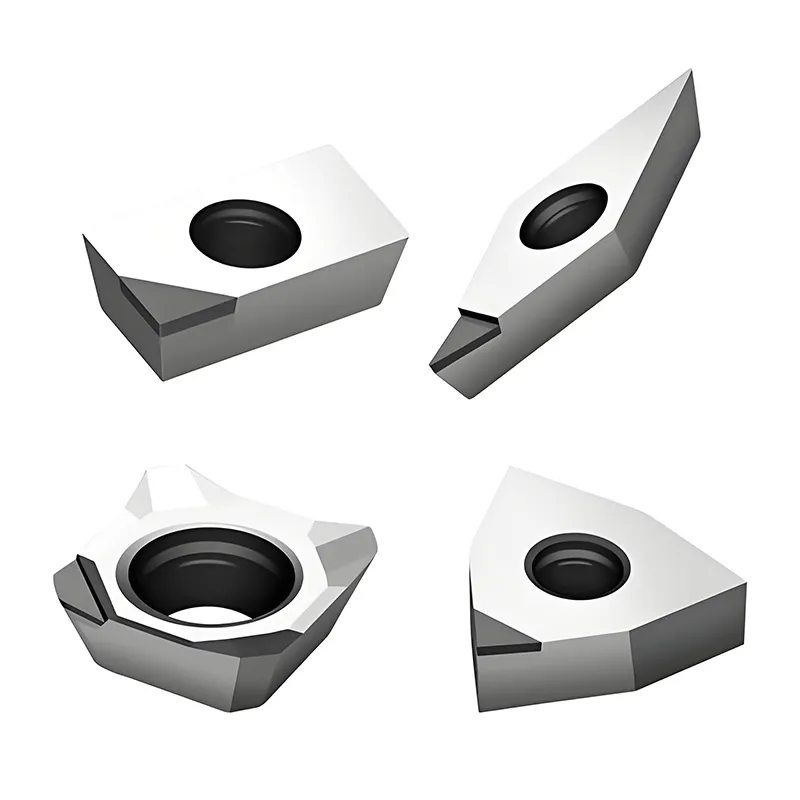

At Ningbo Wangdefu Precision Machinery Co., Ltd., we understand the critical role that CNC Cutting Tools play in modern manufacturing. Our factory is dedicated to producing high-quality CNC blades that deliver precision, durability, and efficiency. However, even the best CNC Cutting Tools require proper maintenance to ensure they provide optimal performance over time. In this article, we will explore key maintenance steps that extend the life of CNC blades, keeping our production lines efficient and cost-effective.

Maintenance Steps to Ensure Longer Life

1. Regular Cleaning

Keeping CNC blades free from debris, coolant residues, and material build-up is fundamental. Our recommended approach is to clean blades after each cutting cycle using appropriate solvents or mild detergents. Our factory emphasizes the importance of avoiding abrasive cleaning materials, which can compromise the cutting edge. By maintaining cleanliness, our CNC Cutting Tools retain sharpness longer and reduce the risk of contamination in high-precision operations.

2. Lubrication and Coolant Management

Proper lubrication is critical to prevent overheating and excessive wear. Our factory ensures CNC blades are used with the correct coolant type and concentration. We advise monitoring the coolant system regularly and replacing fluids as needed. Our CNC cutting tools, when adequately lubricated, exhibit improved chip evacuation and reduced thermal stress, ultimately prolonging their lifespan. Implementing a scheduled coolant inspection routine is part of our standard maintenance practices.

3. Inspection and Edge Maintenance

Routine inspection allows early detection of wear patterns, chipping, or micro-cracks. Our factory employs magnification tools to assess blade conditions accurately. If minor edge dulling is observed, careful re-sharpening using specialized equipment ensures the blade retains its geometry without compromising material hardness. Our CNC Cutting Tools can thus be reused multiple times, maintaining consistent cutting performance and reducing replacement frequency.

4. Proper Storage and Handling

Storing CNC blades correctly is often overlooked but crucial. Our factory recommends keeping blades in protective holders or cases, away from moisture and dust. Handling should always include protective gloves to avoid oil or dirt transfer. By minimizing physical damage and corrosion, our CNC Cutting Tools remain ready for precision tasks, maintaining their integrity over long production cycles.

5. Usage Best Practices

Even with high-quality CNC Cutting Tools, inappropriate usage can reduce lifespan. Our factory advises avoiding excessive feed rates or speeds that surpass the recommended specifications. Our team ensures that operators are trained to match blade types with material hardness and thickness. Consistent adherence to operational guidelines preserves blade sharpness, improves cut quality, and prolongs tool life.

Product Specifications

| Product Name | CNC Cutting Tools |

| Material | High-Speed Steel (HSS) / Carbide |

| Blade Diameter | 3mm - 25mm |

| Cutting Edge Coating | TiN, TiAlN, DLC Options |

| Shank Type | Straight, Weldon, Threaded |

| Application | Milling, Drilling, Engraving, Precision Machining |

| Recommended RPM | 5000 - 25000 RPM depending on material |

| Service Life | Up to 2000 cutting hours with proper maintenance |

| Manufacturer | Ningbo Wangdefu Precision Machinery Co., Ltd. |

| Warranty | 12 months limited warranty |

FAQ: What Maintenance Steps Ensure Longer Life For CNC Blades?

Q1: How often should CNC blades be cleaned to maintain their lifespan?

A1: CNC blades should be cleaned after every cutting cycle. Our recommendation is to use a mild detergent or specialized solvent that removes debris and coolant residues without scratching the cutting edge. Consistent cleaning prevents material build-up and corrosion, ensuring the CNC Cutting Tools maintain precision.

Q2: Can improper lubrication reduce the life of CNC blades?

A2: Yes, inadequate lubrication can cause overheating and excessive wear. Our factory ensures CNC blades are used with suitable coolants at recommended concentrations. Regular monitoring and replacement of lubricants are essential to minimize thermal stress and friction, which directly impact the blade’s durability.

Q3: What is the best method for storing CNC blades when not in use?

A3: Blades should be stored in protective holders or cases to prevent physical damage and exposure to moisture. Our factory emphasizes handling blades with gloves to avoid contamination. Proper storage prevents corrosion and maintains cutting accuracy, prolonging the CNC Cutting Tools’ service life.

Conclusion

Ensuring the long life of CNC blades requires a combination of proper cleaning, lubrication, inspection, storage, and adherence to operational best practices. At Ningbo Wangdefu Precision Machinery Co., Ltd., our CNC Cutting Tools are engineered for excellence, but our experience shows that following these maintenance steps maximizes their performance and durability. By implementing these strategies in our factory and sharing them with customers, we support efficient production, reduced costs, and extended tool life, ensuring consistent quality in all machining tasks.