What is the Use of a Block Making Machine?

2024-11-29

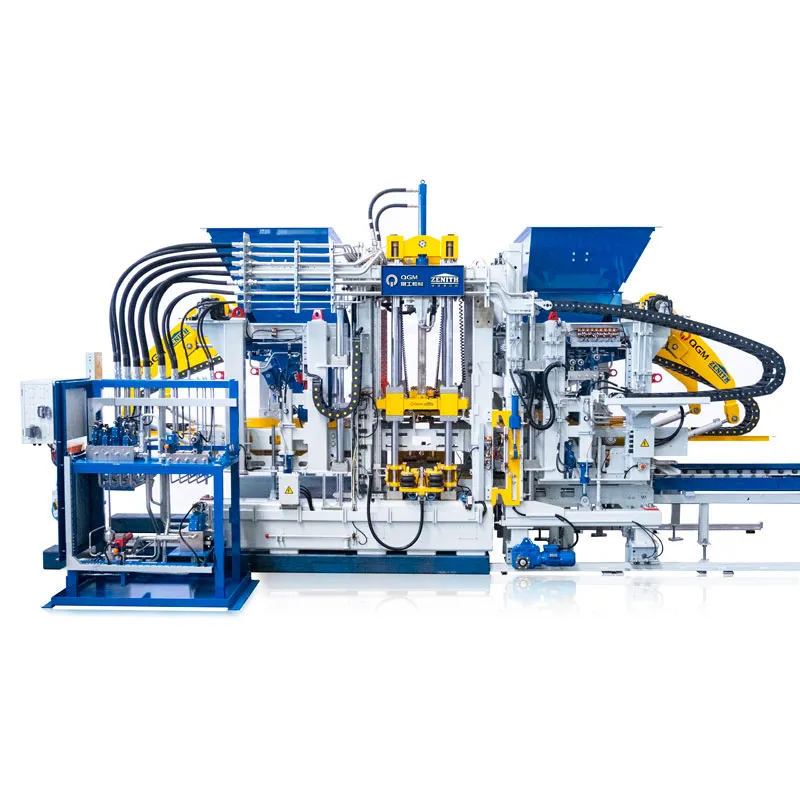

A block making machine, also known as a block machine or brick making machine, is a piece of equipment used to manufacture concrete blocks, cement bricks, hollow blocks, interlocking pavers, and other construction materials. These machines are essential in the construction industry, where they help to produce uniform, durable building blocks that are used for a wide variety of applications.

Here’s a detailed look at the uses of block making machines and how they contribute to the building and construction process:

1. Producing Concrete Blocks and Bricks

The primary use of a block making machine is to produce concrete blocks and bricks for construction purposes. These can range from solid blocks to hollow blocks, depending on the needs of the project.

- Solid blocks: Used for walls and foundations, providing strength and stability.

- Hollow blocks: Often used for building lightweight walls or partitions, offering better insulation and reducing construction costs.

- Paving blocks: Used for roads, driveways, and pavements, providing durability and aesthetics.

- Interlocking blocks: Designed to fit together without the need for mortar, making them ideal for flooring, walls, and outdoor landscaping projects.

2. Construction of Buildings and Infrastructure

Block making machines are widely used in the construction of residential, commercial, and industrial buildings. The concrete blocks they produce are fundamental for building walls, floors, foundations, and other structural elements. The strength, durability, and versatility of concrete blocks make them a preferred choice for most construction projects, whether in urban or rural areas.

3. Creating Prefabricated Concrete Products

Block making machines are also used to create prefabricated concrete products that are manufactured off-site and then transported to the construction site for assembly. These prefabricated products can include:

- Precast walls: Ready-to-install walls that speed up construction times.

- Concrete panels: Used in both residential and commercial buildings.

- Concrete blocks for foundations: These can be custom-made for specific projects, ensuring quality and precision.

4. Cost-Effective Construction Solutions

Block making machines help reduce construction costs in several ways:

- Reduced labor costs: The automation of block production minimizes the need for manual labor, leading to a reduction in overall labor costs.

- Efficient material usage: Block machines are designed to optimize the use of raw materials, such as cement, sand, and aggregates, reducing waste and lowering material costs.

- Faster construction: The production of uniform blocks speeds up the overall construction process, as they can be produced in large quantities in a short period.

5. Environmentally Friendly Construction

Some block making machines are designed to use recycled materials such as industrial waste, fly ash, and other sustainable inputs. This helps to reduce the environmental impact of construction and contributes to more eco-friendly building practices. Furthermore, concrete blocks can be highly durable and energy-efficient, offering long-term sustainability in building projects.

6. Versatility in Block Types and Sizes

Block making machines offer flexibility in the types of blocks they can produce. Whether it's solid, hollow, or interlocking, these machines can be adjusted to produce different sizes and shapes based on the requirements of the project. This versatility makes block making machines suitable for a wide range of applications:

- Residential construction: For building houses, apartments, and other structures.

- Commercial and industrial buildings: Large-scale projects, such as office buildings, factories, and warehouses, rely on concrete blocks for both structural and aesthetic purposes.

- Landscaping: Paving blocks, garden walls, and other outdoor features can be produced with ease using a block making machine.

7. Reducing Dependency on Traditional Building Materials

Block making machines help reduce dependency on traditional building materials such as bricks made from fired clay. With the rising demand for eco-friendly materials, concrete blocks offer a more sustainable alternative, especially in areas where clay is scarce or costly to obtain. Moreover, the use of locally available aggregates and the ability to customize concrete mix ratios make block making machines ideal for regions with limited access to conventional building materials.

8. Customization for Specific Projects

Modern block making machines often come with advanced features that allow for the customization of concrete blocks for specific building needs. Whether it’s adjusting the density of the block, adding color pigments, or changing the texture, block making machines can be tailored to produce high-quality, customized products for a variety of construction styles and needs.

Conclusion

The use of block making machines is fundamental in modern construction. These machines enable the mass production of concrete blocks, paving stones, and other prefabricated concrete products, helping to speed up construction processes while ensuring durability and cost-effectiveness. With the ability to produce customized blocks for specific applications, block making machines are a key component in the construction of residential, commercial, and infrastructure projects around the world.

If you're involved in the construction industry or looking to start your own concrete block production business, investing in a block making machine is a smart move that offers efficiency, sustainability, and long-term cost savings.